PRODUCTS

PRODUCTS

T

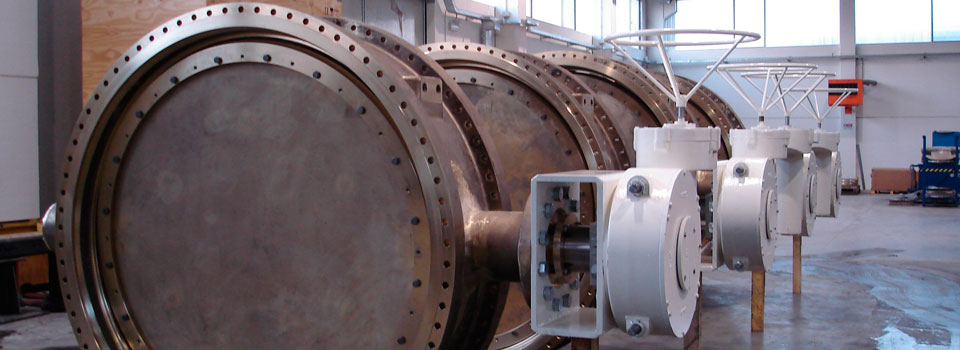

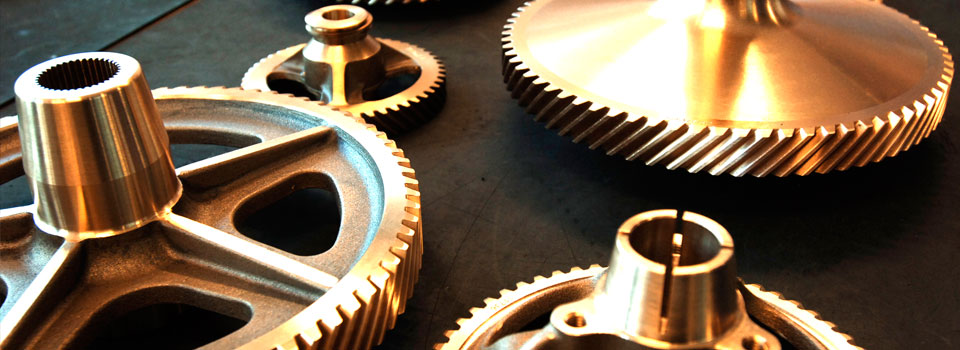

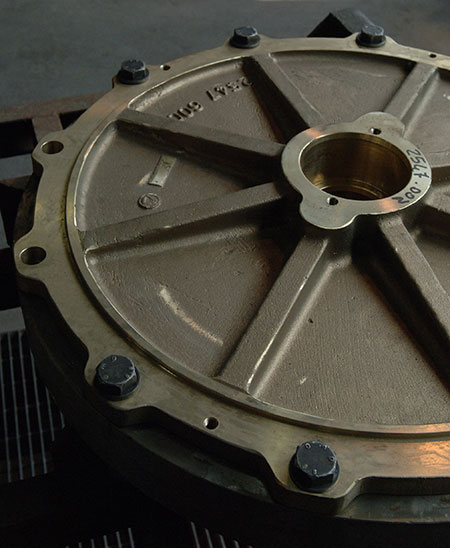

hanks to the technical service developed in the last years and availability of technically advanced plants and equipments, Arno Metallurgica makes high quality castings, with composite quality requirements, either sand cast with hand or mechanical moulding, having weight up to 8000 kg, or realized by horizontal or vertical centrifugal casting. All pieces may be subsequently submitted to heat treatment and/or non-destructive examinations and supplied rough or fully finish machined.

Arno Metallurgica is furthermore always open to new production experience, counting on its own company know-how. It actually seldom works on large series productions, but normally realizes on drawing products required for different needs, making itself an active partner with customers. Then metals and non traditional alloys, such as titanium with chromium-copper, bearings and rotating electrodes for zinc plating plants, items and special valves for cryogenic environments, are typical foundry parts integrated with the supply of finish machine assemblies.

The groups of products usually supplied to a wide range of companies in Italy and abroad are reported in the following:

• Castings for industry: pump bodies and runners, valve bodies and shutters (butterfly, stop, globe, etc.), components for centrifugal separators, gears, evaporators and components for electrochemical plants, etc.

• Components for marine field and off-shore platforms: pipes and surface plates for fire-fighting plants of oil platforms, propellers, variable pitch propellers (hub and blades), valve and components for naval pumps and desalination plants, evaporators and items for on-board desalination equipments, bushing for propeller shafts.

• Energy production: Pelton, Francis and Kaplan runners, retaining rings, valves, etc.

• Electrical industry: components for transformers and generators.

• Zinc plating electrolytic plants: rotating electrodes and current-carrying bearings.

English

English