CERTIFICATIONS

SYSTEM CERTIFICATIONS

• Our Quality System was developed at the beginning of years ’90 according to ISO 9002 and verified conforming in 1994 by det norske veritas, certificate no. 176, for the following field of application: “Foundry for manufacturing and processing of castings in copper and copper alloys, aluminium bronze and nickel bronze”. Subsequently the system was updated to uni en iso 9001:2000 standard, subject to surveillance audits always by the same certifying body.

• At present we are operating to realize the Environmental Management System according to the requirements of uni en iso 14001 standard, powerful method for continuously improve the management of environment variable inside the company.

PRODUCT CERTIFICATIONS

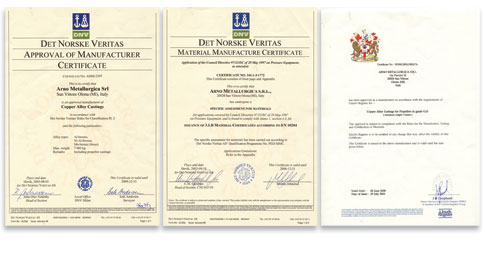

• European Pressure Equipment Directive (PED), related to the conformance of design, manufacture and the conformity evaluation of equipment subject to a pressure hazard. Certified in 2002 by the Notified body Det Norske Veritas.

• Approval released in 2005 by det norske veritas for the manufacture of copper alloy casting, in particular aluminium bronzes and brasses, up to 7000 kg weight for valves, pumps, propellers and other items in marine application.

• Approval released in 2005 by lloyd’s register for the manufacture of castings for copper alloy marine propellers with maximum weight of 7000 kg.

• Approval released in 2005 by lloyd’s register for the manufacture of castings for copper alloy valves and other marine items with maximum weight of 4000 kg.

PERSONNEL CERTIFICATIONS

• Operators and technical staff performing non-destructive examinations of liquid penetrants and ultrasonic are qualified level 1 and 2 for methods used in the company by cicpnd and iis.

• The company furthermore has the contribution of a level 3 expert, certified by cicpnd in six non destructive and three metallographic methods.

• Welders qualified in adopted processes, according to asme standards, perform welds.

English

English